Summer 2020 Internship at Formulatrix

After Freshman year I returned to the R&D department at Formulatrix, this time to research low cost flow measurement systems for the company’s new Liquid Handler, the FLO I8. This project took me through a wide variety of engineering topics including: Acyrlic micromachining, C for Arduino, microfluidics, basic PCB design, electrical component selection, international collaboration, and test equipment design.

The general principle of the flow sensor is identical to that of a resistive ammeter, create a restriction and measure the energy (pressure in this case) drop across it to find the flow rate.

A wide variety of pressure manifold designs were investigated for single and dual path flows (using PEEK restrictive tubing).

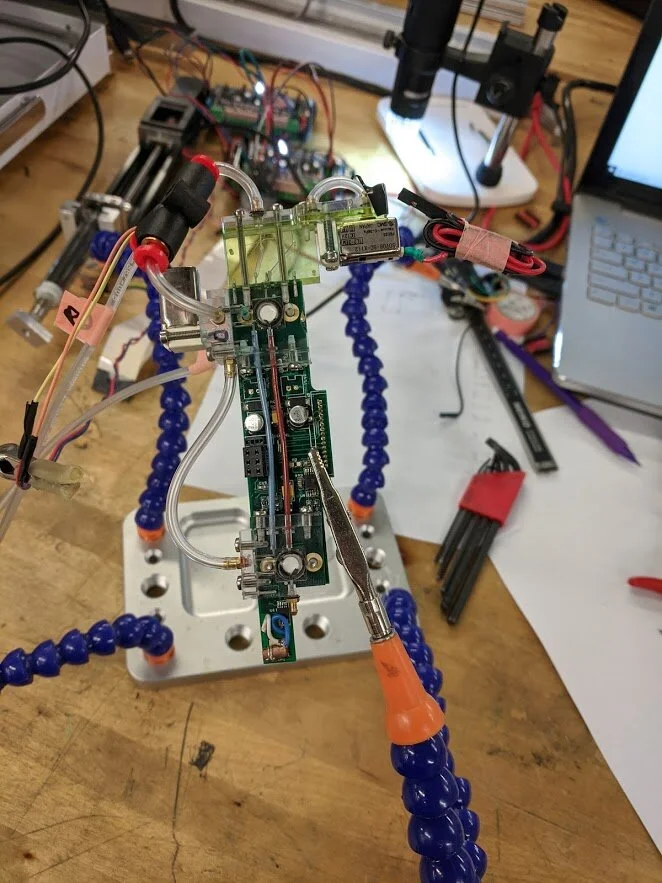

Custom PCBs were manufactured to support a variety of sensor configurations. This design utilized a stainless steel orifice plate as its flow restriction.

A switching mechanism was developed to allow the system to select its desired flow rate range for a specific aspirate/dispense cycle.

An Arduino based testing system interfaced with the sensor and a custom syringe pump to repeatably qualify a given sensors restriction, allowing us to validate the governing equations of the system.

Leak testing was critical to ensure assembly errors did not affect collected data.